Refractory metals generally refer to metals whose melting point is higher than 1650℃ and have certain reserves. Generally, they include tungsten, rhenium, tantalum, molybdenum, niobium and iridium and vanadium. Their melting points are tungsten 3390℃, rhenium 3180℃, tantalum 2996℃, molybdenum 2620℃, Niobium 2468℃, iridium 2410℃ and vanadium 1890℃. The most important advantages of refractory metals are good high temperature strength, good corrosion resistance to molten alkali metals and steam, its main shortage is poor high temperature oxidation resistance. There are four ways to strengthen refractory metals: solid solution strengthening, work hardening, precipitation strengthening and dispersion strengthening. Application areas including steel and non-ferrous metal alloy additive, mining tool, cutting tool, processing mould, as well as parts material of electronic, electric light source and electrical etc areas, corrosion resistant parts of chemical engineering, heating element and heat insulation screen of high temperature and high vacuum department, armor-piercing core, radiation protection material, instrument parts, hot working tools and welding electrodes, etc.

Our group has more than 50 years of research and development and production experience in refractory metals and their alloy materials and products, our advantages are leading in China, and we have achieved tens of national and provincial scientific and technological achievements

| Iridium crucible |

Standard:Qn/YCS 214—2012

Quality:Ir≥99.95%

Product size: OD≥110mm,height≥110mm

Features:density 21.5g/cm3 minimum,compactness≥98%,when the iridium crucible is filled with kerosene for 24 hours, no leakage, the average life is 18 heats.

Application:For photovoltaic industry, optics and optoelectronics field, it is used as growth container for high melting point single crystal such as yttrium aluminium garnet (YAG), germanium gallium garnet (GGG) and ruby.

| MS type molybdenum disilicide thermocouple protective tube |

◆ Features

Ms type molybdenum disilicide thermocouple protective tube is a cermet product based on refractory metal compound molybdenum disilicide. It not only overcomes the disadvantages of poor thermal impact resistance, air tightness and mechanical properties of Al2O3 protective pipes, but also has the characteristics of high temperature corrosion resistance, oxidation resistance, air scour resistance, good thermal stability, no phase change and so on. And it is suitable for using in oxidation, reduction, oxidation-reduction alternating atmospheres as well as neutral, certain chemical corrosive gases, molten metals and other mediums. This product has been widely used in natural gas development, chemical fertilizer, metallurgy, refractory, ceramics, cement, petrochemical, coal chemical, carbon black, machinery and other industries, the effect is good.

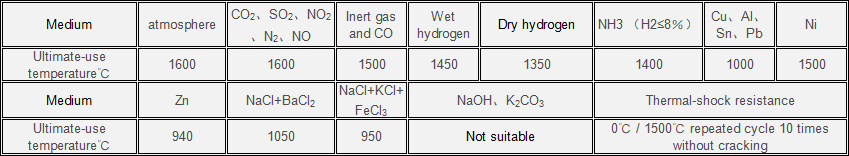

◆ Heat resistance and corrosion resistance

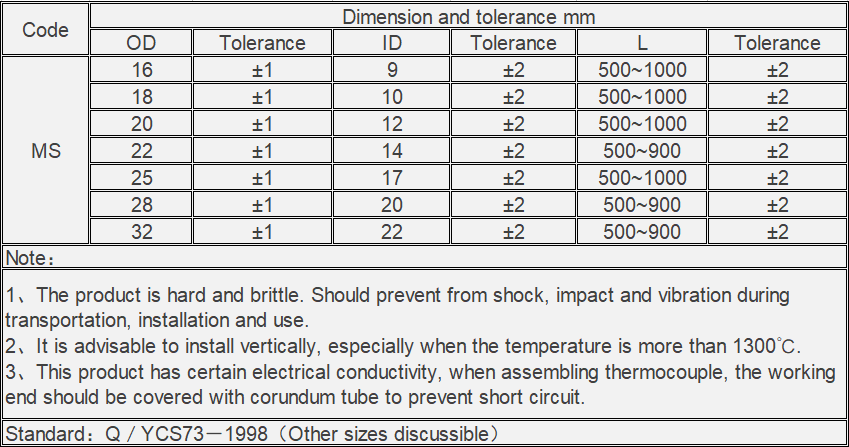

◆ Dimension and tolerance

| High performance tungsten rhenium alloy |

Tungsten-rhenium alloy is composed of tungsten and rhenium. One is low rhenium alloy, containing less than 5% rhenium; the other is high rhenium alloy with 20-30% rhenium content. The method of preparation is similar to that of tungsten. The main application is the filament of special electron tube and color picture tube, high temperature parts which requires high strength and high plastic. The matching of low rhenium alloy and high rhenium alloy can be used for high temperature thermocouple for testing temperature of 1500-3000℃.

Rhenium effect: 3-5% rhenium is often added to doped tungsten wire, which is called tungsten rhenium wire. It can reduce the ductility transition temperature of tungsten to room temperature or below. This is a very peculiar rhenium effect, so far no element has been found to replace rhenium, which has the same effect in tungsten.

Process:Preparation of raw materials → separation of raw materials → mixing → reduction treatment → 2nd mixing → Pressing sintering → rotary swaging → drawing → finish processing

Application:Material applications: for color picture tube hot wire, various electronic tube filament and grid.

① Tungsten filament lamps with special requirements, chromatographic heat sensitive elements

② Heating wire mesh for television heating and picture tube and camera tube

③ For military electronic equipment

Our technical breakthrough:

① Composition Design and Optimization of Tungsten Rhenium Alloy

② Purification of tungsten rhenium alloy raw materials

③ Preparation of superdispersed and highly active tungsten-rhenium prealloyed powders

Main products

| ① WRe thermocouple wire for rapid measurement of liquid steel temperature |

Note:

a、The guaranteed precision range of thermo wire is 1500~1800℃

b、t for temperature to be measured

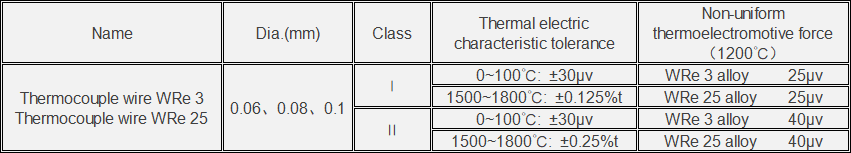

| ② WRe thermocouple fine wire |

◆ Standard:JB/T 9497-2002

◆ Application condition:It is used in vacuum, hydrogen, inert atmosphere with a temperature range of 0~2300℃.

Non-uniform thermoelectromotive force

For whole coil of thermo wires, when at 1200℃,its non-uniform thermoelectric electromotive force of positive or negative: Class 1 thermo wire ≤40μV, Class 2 thermo wire ≤80μV.

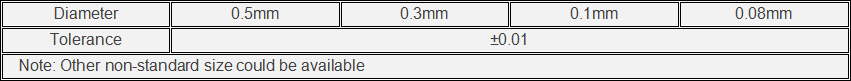

◆ Thermo wire diameter and tolerance

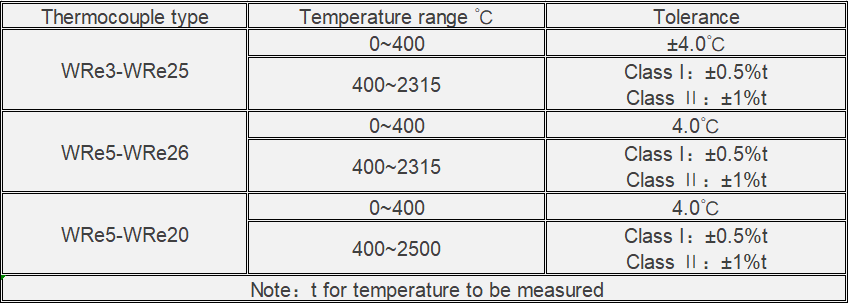

◆ Thermoelectric properties and tolerance

For thermocouple consisting of thermo wires, when the temperature of the reference end is ℃, tolerance for the temperature and the thermoelectric potential

| ③ WRe alloy flat strip |

Features:Good strophism, good heat resistance, electric resistivity ρ≤0.12μΩ·m

Property:The surface is smooth after 10 circles winding on a dia.1.6mm mandril.

Size:T0.16mm x W0.50mm

Application:It is a key material for the power line and power tube of the satellite system engineering, also can be used in high temperature and fast foil temperature measurement.

| Molybdenum rod, wire and tube |

◆ Molybdenum rod and wire

Property:High melting point, high temperature resistance, resistance to corrosion in reductive atmosphere, suitable for use in vacuum and reductive atmosphere.

Purity:Mo1≥99.93%Mo, Mo2≥99.90%Mo

Size:Dia.0.10-3.00mm

Application:Electric vacuum device, electric light source gate wire, hanging hook, core wire, wire cutting element, high temperature sintering furnace, heat treatment furnace heater, surface spraying material, etc.

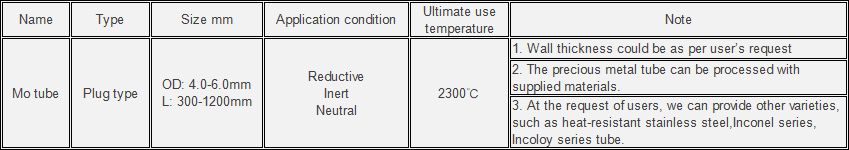

◆ Mo tube(Heat resistant alloy protective tube)

| Other refractory metal material and product |

Our company can also produce other refractory metal material and product listed below

① W.Mo material

② Cermet material

◆ Ingot:Dia.≤900mm

◆ Bar:Dia.≤450mm

◆ Tube:OD4.0-450mm

◆ Wire: Dia,0.1-12mm

◆ Plate & strip:T0.05-20mm

◆ Forging:as per drawing or agreement

◆ Capillary: smallest size is Ф1.0×0.05mm

◆ Heavy plate: Single weight could be 3MT max.