| SHAPE MEMORY ALLOYS |

Shape memory alloy (SMA) is a kind of material composed of more than two metal elements with shape memory effect through thermoelasticity, martensitic transformation and inversion. Titanium-based, copper-based and iron-based shape memory alloys have been used at present. Nitinol shape memory alloys are the most comprehensively studied and best one. They have the characteristics of high strength, high plasticity, good corrosion resistance, good stability and excellent biocompatibility. The superiority of its application in medicine is that other shape memory alloys can not be replaced.

Nitinol is a term for binary near equal-atom Ni-Ti alloys, and it is widely used in medical due to its unique super-elasticity. However, Ternary or other Nickel-Titanium alloys can be achieved for different properties. All incoming Nitinol raw materials are subjected to third party inspection to ensure they meet proprietary specifications for chemistry, transformation temperature, material homogeneity, and microstructure. To promote an exceptionally smooth and uniform surface finish quality, all wire and tube products utilize a high precision single and/or multi crystalline diamond drawing die technology to reach the final wire diameter. After heat treatment, nickel-titanium materials can undergo up to 8% strain at human temperature without permanent bending.

The chemical composition is as per ASTM F2063-12 or GB 24627-2009(wt%), Ni 54.5-57, C ≤0.050, Co ≤0.050, Cu ≤0.010, Cr ≤0.010, H ≤0.005, Fe ≤0.050, Nb ≤0.025, N+O ≤0.050, Ti balanced.

Reference to standards and documents

ASTM F2063-12/GB 24627 Standard chemical composition of a wrought nitinol shape memory alloy

used in medical devices and surgical implants

ASTM F2633-13 Standard specification for seamless nitinol shape memory alloy fitting

for medical devices and surgical implants

ASTM F2005-05 Standard terminology for nitinol shape memory alloys

ASTM F2004-05 A standard test method for the transition temperature of Nitinol alloy

by thermal analysis

ASTM F2516-14 Tensile test method for nitinol hyperelastic materials

ASTM F2082-15 The standard test method for phase transition temperature of nitinol

shape memory alloy by bending and free restoration.

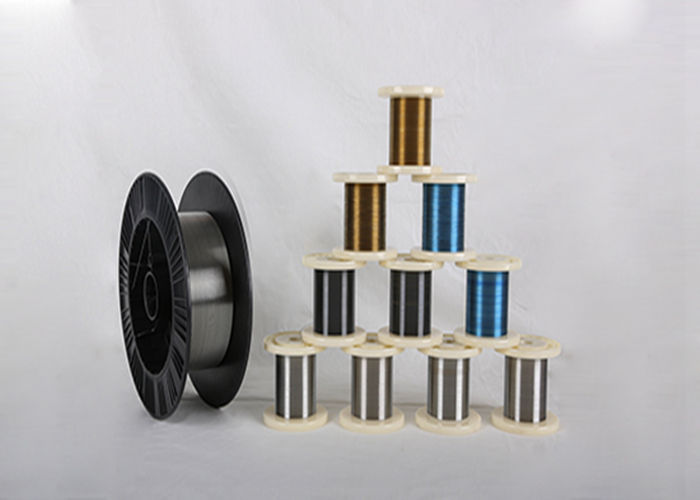

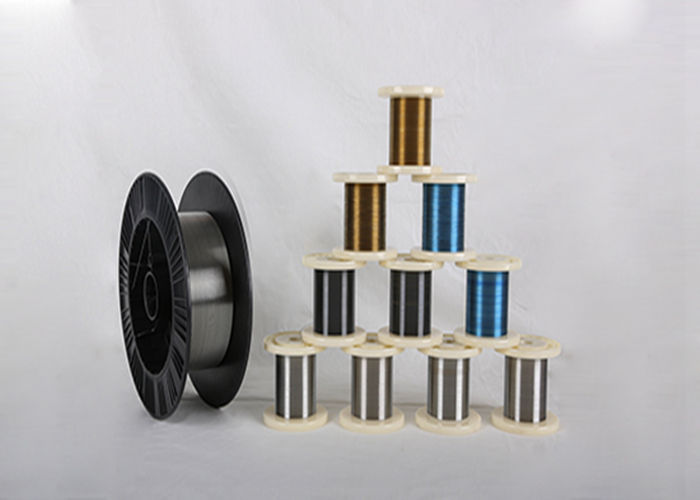

| 1、Nitinol wires |

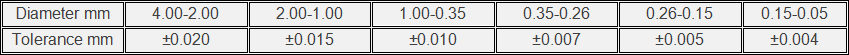

(1) Nitinol wire diameter and tolerance

* Out of roundness within half of the diameter tolerance.

(2) Delivery condition

① Straightened hyperelastic(SE)

② Cold worked (CW), subsequent heat treatment required

(3) Wire surface condition

① Black surface oxidation status

② Light oxidation status (from golden to brown)

③ Clean

④ Bright

⑤ Super bright

⑥ Centerless ground

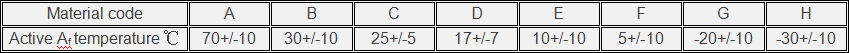

(4) Material code

Active af temperature is one of the critical properties of Nitinol that can determine the effective super-elastic performance of the alloy. Although all the major Ni content in the range of 54.5~57.0mass% conforms the ASTM F2063-12 standard spec, its af is very sensitive to the chemical composition, detailed grading of Nitinol composition is of crucial importance. This is why we use detailed and verified material code to identify the alloy.

(5) Typical medical application

Guide wire, woven support, dental root file, dental arch wire, iud, suture line etc

| 2、Nitinol tube |

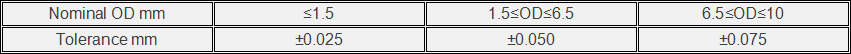

(1) Nominal dimension and tolerance

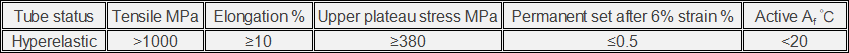

(2) Mechanical properties at room temperature

(3) Surface condition

① OD surface:Oxide, centerless ground

② ID surface: clean, oxide

(4) Active Af temperature

The austenite finish temperature of the finished tube (active Af) with outer diameter in the range of 0.3 to 3.0 mm (0.012 to 0.12 in.) shall be measured on representative full round tube sample(s) using the bend and free recovery method described in Test Method ASTM F 2082-15.

| SOFT MAGNETIC ALLOYS |

Soft magnetic alloy refers to the magnetic alloy with coercivity of Hc<1kA/m, which is characterized by low coercivity and low core loss, and easy magnetization under the action of external magnetic field.This kind of alloy is widely used in various transformer, motor, relay, electromagnet, magnetic recording, magnetic shielding, telecommunication engineering and telemetry remote sensing system and as a magnetic component in instruments. Due to different requirements on magnetic alloy in application, it has been developed into a variety of alloys.

| 1、Electromagnetic stainless steel |

Our electromagnetic stainless steel has good magnetic property, easy to cut, and extremely low leakage rate. All the performance indexes meet the standard. Some products can completely replace imported materials from Japan, Germany, Italy and other countries.

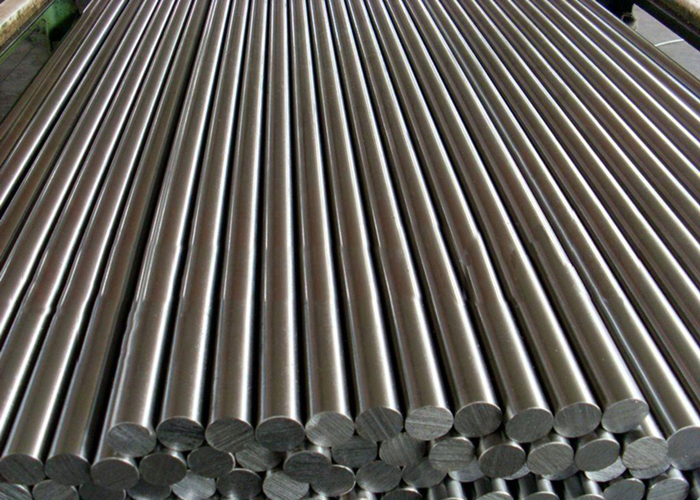

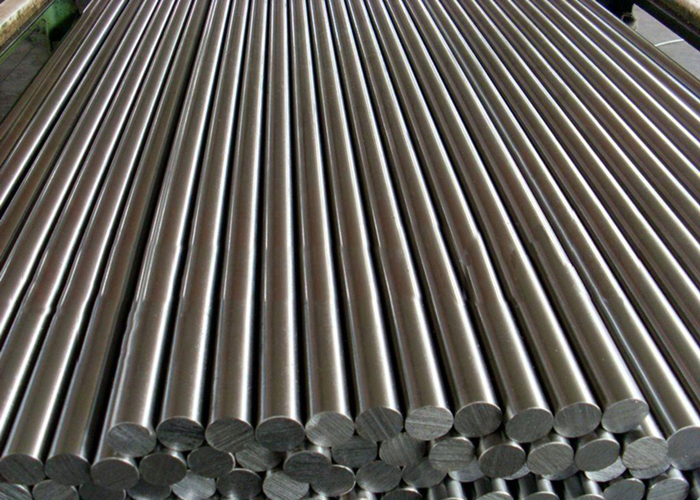

Billet: Dia.30-50mm small billet by horizontal continuous casting machine

Product size: Dia.4.0-41.0mm

Surface condition: centerless ground

Material grade

China:00Cr13Si2, 00Cr13Si2S, 00Cr13Si2Pb, 0Cr15Si2PbS, 0Cr17Si2, 0Cr17Si2Mo, 00Cr17Si2S, 0Cr17Si2Pb, 00Cr18Si2Mo2,

85Cr18Mo2V, 45Cr9Si3, 33Cr23Ni8Mn3N, 61Cr21Mn10Mo1V1Nb1N, 45Cr14Ni14W2Mo, 53Cr21Mn9Ni4N, 55Cr21Mn8Ni2N

Japan:K-M25F, QMR1L, K-M31, K-M31S, K-M35F, K-M35, K-M37F, K-M38

Germany:4016IM, 4105IL, 4105IM, 4113IL, 4113IM

USA: AISI 405, AISI409, AISI 416, AISI429, AISI430, AISI430FR, AISI 434

Italy:MG1, MG2

| 2、Other magnetic alloys |

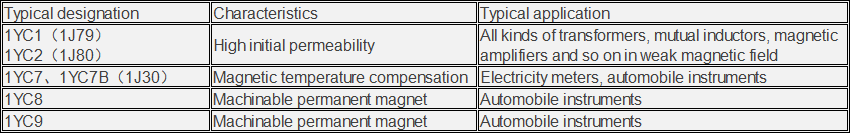

◆ Typical grade

Note:1YC® is product grade of Chongqing Material Research Institute.

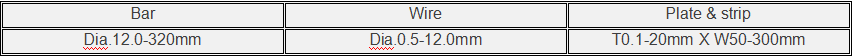

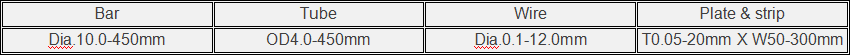

◆ Product size

| ELASTIC ALLOYS |

Elastic alloys are used in making elastic sensitive components, energy storage components and frequency components in precision instruments. In addition to good elastic properties, it also has non-magnetic properties, micro-plastic deformation, high resistance, high hardness, low resistivity, small temperature coefficient of elastic modulus, small internal consumption and other properties.

Elastic alloys include high elastic alloys and constant elastic alloys, the former has high elastic limit, low anelastic effect and good heat resistance. The latter is called Elinvar alloy, whose elastic modulus varies little within a certain range of temperature. Elastic alloys are usually smelted in vacuum, and semi-finished or finished products are often heat-treated in a vacuum or protective atmosphere.

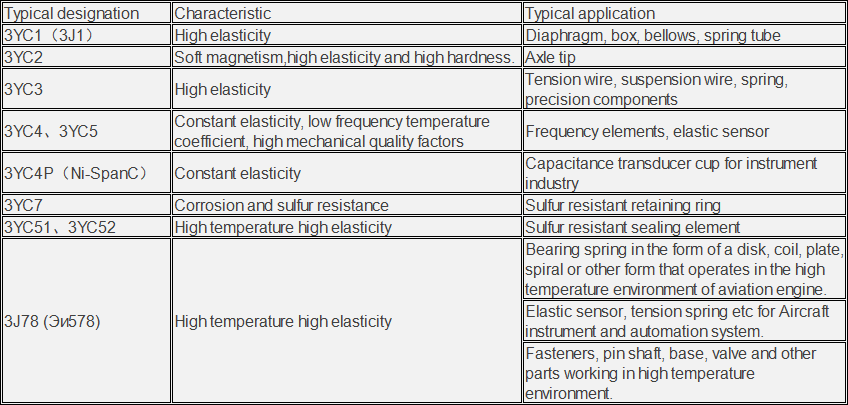

◆ Typical grade

Note:

1) 3YC, GYC are material designation of Chongqing material research institute, and 3YC® is its registered trade mark.

2) For our self-owned brand 3YC4P, it has a market share of 50% in China.

3) 3J1,3J9 are also our self-owned brand.

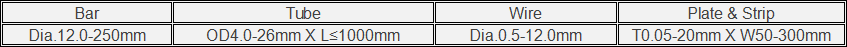

◆ Product size

| EXPANSION ALLOYS |

Expansion alloy is a kind of precision alloy with abnormal thermal expansion, also called thermal expansion alloy. It is widely used in electronic industry, precision measuring tools, precision instrument and low temperature engineering. The expansion alloys mainly include Fe-Ni system, Fe-Ni-Co system, Fe-Ni-Cr system and so on. In addition to the specific coefficient of thermal expansion, expansion alloys require good sealing, weldability, corrosion resistance, processability and easy cutting according to different applications. In addition, no phase transition is allowed in the range of operating temperature, which causes obvious changes in the expansion characteristics. The chemical composition of the expansion alloy must be controlled accurately in the process of manufacture.

According to the expansion coefficient, expansion alloy can be divided into three types: high expansion alloy, low expansion alloy and fixed expansion alloy.

High expansion alloy used chiefly as an active layer of thermo bimetal.

Low expansion alloy, also known as Invar alloys, is mainly used as an element in instruments whose size is approximately constant with the change of temperature, such as precision balance arm, standard pendulum rod, pendulum wheel, length ruler, geodetic reference ruler, resonator, microwave communication wave guide, standard frequency generator, etc. It is also used as a passive layer for thermo bimetal.

Fixed expansion alloy is also called sealing alloy because it is close to the expansion coefficient of glass, ceramics or mica, and can be matched and sealed with them. It is widely used for sealing, lead and structural materials in electronic vacuum devices, such as electronic tubes, transistors, integrated circuits and so on.

◆ Fe-Ni-Co glassy sealed alloy FeNi29Co17

Grade:4J29( Kovar) ,also called Kovar alloy(Fe54%、Ni29%和Co17%),it expansion coefficient is 4.7×10-6/℃。

Standard:YB/T 5231-93

Application: Often being used to make hard glass sealing. Suitable for transmitting tube, oscillating tube, igniting tube, transistor, tube seal plug, relay shell and other electric vacuum devices. In the temperature range of -60℃ up to +400℃, there is a certain coefficient of linear expansion, which can match and seal the hard glass firmly.

◆ Ceramic sealing alloy

Grade:Vacodil42, 4J42, 4J33, 4J34

Standard:YB/T 5234-93

Application:Often being used to make ceramic sealing, it is suitable for the matching and sealing of electric vacuum device and 95% Al2O3 ceramics. The linear expansion coefficient is similar to that of 95% Al2O3 ceramics in the temperature range of -60℃ ~ +600℃.

For many years, we have been the sole licensed supplier of China Aerospace 4J32B

On the basis of low expansion alloy 4J32, our group company has developed 4J32B, fixed expansion alloy 4J32C and negative expansion alloy 4J32D series. 4J32B is high strength, high modulus, ultra low expansion alloy. The coefficient of thermal expansion (α≤0.5x10-6/℃) is extremely low in the range of atmospheric temperature variation. Its plasticity is good, its performance is stable, and its thermal conductivity is poor. It is mainly used in the manufacture of parts with high accuracy in the range of environmental temperature and precision instruments which require very low coefficient of expansion of constant size near normal temperature. resonator parts and thermal bimetallic passive layer, and other devices with small temperature drift ratio frequency elements, standard scale, astronomical instrument frame, etc. Especially the successful application for the space remote sensor ensures the transmission of high quality information in the high altitude complex environment.

◆ Product size