The company can supply extruded, CR or CD superalloy pipes for use at ambient temperature up to 1300℃. The products are widely used in aviation, aerospace, petrochemical, metallurgy, machinery, energy, power, nuclear industry and building materials. It meets the harsh requirements of high temperature, thermal ablation, wear and various acid, alkali, salt environments.

Production process

Hot process: Extrusion + Perforation (pierced billet)

Cold process: CR + CD + Cold broaching (green pipe)

NDE: Eddy current inspection + UT + Hydraulic pressure inspection (Finished pipe)

Extruded pipe

Size:OD60~325mm X WT6~40mm X L3000~18000mm

Single pipe weight 550kg max.

Deep hole drilled pipe (Gun drill drilled pipe): ID3-20mm

Inner hole diffractive grinding tube: ID3-300mm

CR or CD pipe

Size: OD20~273mm X WT1.65~32mm X L≤13000mm

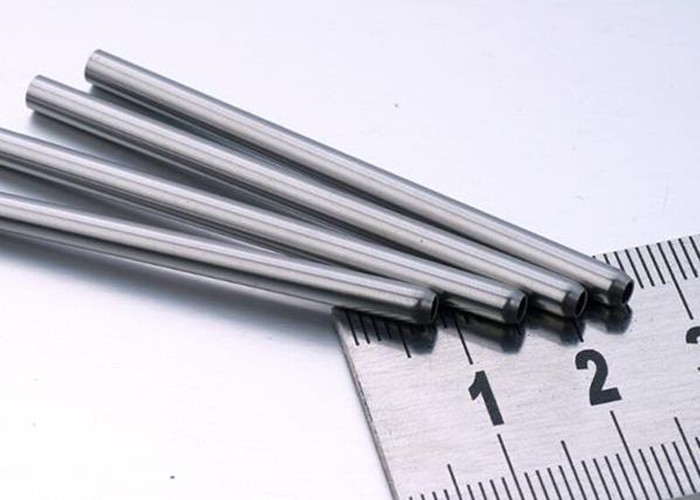

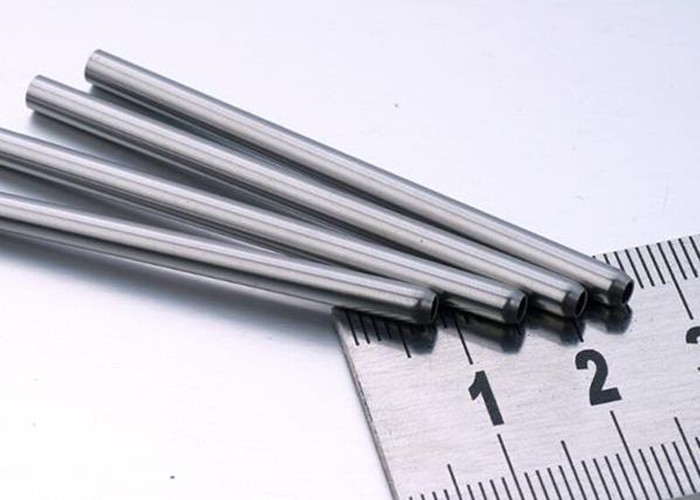

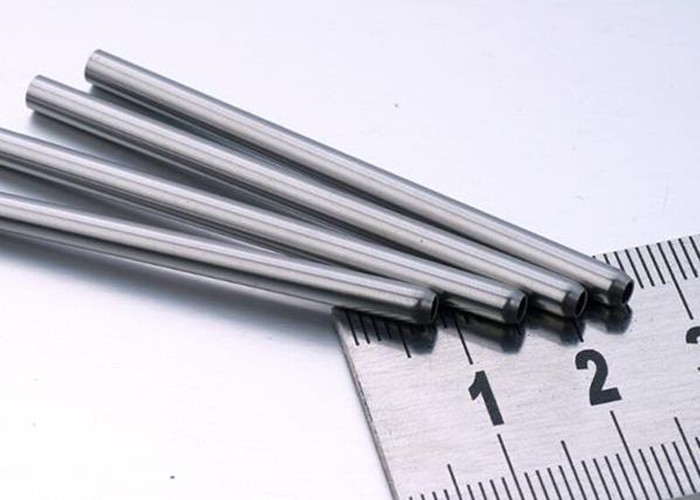

Capillary

Size: OD0.2~8mm X WT0.015~0.5mm

Best tolerance: OD±0.003mm, WT±0.005mm, L±0.03mm

Appearance: Observed by the microscope, the inner and outer surfaces of the tube show a uniform metallic luster, no oxidation, hydrogenation discoloration, scratches, deformation, burrs and so on.

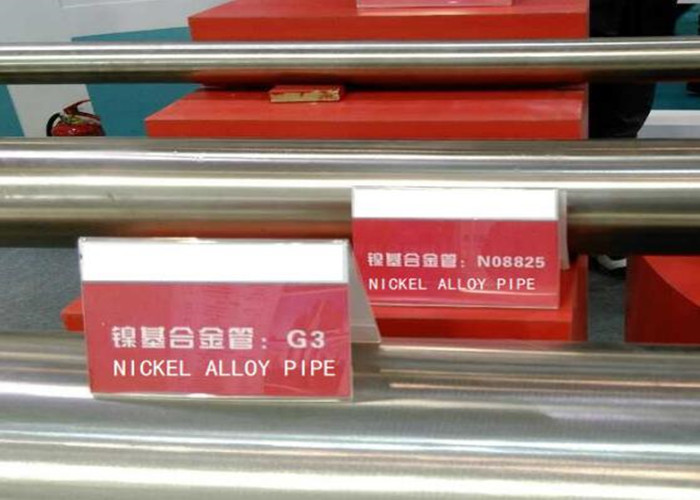

Main grade

For protective casing: GH747, GH214, GH455

Capillary: GH3128, GH3044 (ЭП868), GH4169 (Inconel718)

For nozzle: GH5188, Haynes 188(HA188),UNS R30188,KCN22W, Co50,GH3652、GH3181, GH4169 (Inconel718),GH3030 (NC20T, ЭП435, HR5, DTD703B, N203, N403), GH4202, ϶Π202

Inconel series: Inconel 600, Inconel 601, Inconel 625

Incoloy series: Incoloy800, Incoloy 800H, Incoloy825

Monel series: Monel 400, Monel K500

Hastelloy series: Hastelloy C, Hastelloy C-276, Hastelloy X, Hastelloy B, Hastelloy C4、Hastelloy C6

Haynes series: Haynes 25, Haynes 188

*Please note that not all the alloys are available in all forms, weights and sizes.